EDGECAM’s 5-Axis Toolpaths Wax Lyrical for Tooltech

A wax injection and mould tool manufacturer has recently invested in 5-axis technology to dramatically reduce production time.

While researching 5-axis capability, Tooltech Director Mark Newcombe discovered that a job similar to one taking two days to complete with their 3-axis machines, was being done in 25 minutes on a 5-axis machining centre.

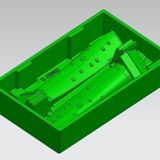

“Also at that time, we produced a tool with ten set-ups on the block as it had some extremely complex features on it, and it took us three weeks to manufacture. A 5-axis machine, programmed with EDGECAM software’s 5-axis module would have completed it in a week, with only three setups.”

Mark Newcombe, Tooltech Director

“Also at that time, we produced a tool with ten set-ups on the block as it had some extremely complex features on it, and it took us three weeks to manufacture. A 5-axis machine, programmed with EDGECAM software’s 5-axis module would have completed it in a week, with only three set-ups.”

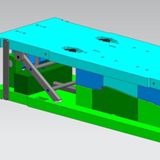

Devon based Tooltech design and manufacture wax pattern tooling for investment casting industry along with all the auxiliary tooling required for a full tooling suite, this includes, cut-off and power grind fixtures, along with all types of CMM fixtures, for the power generation and aerospace products. “Customers come to us with a part model and we design and manufacture the tooling for them. We have a good reputation for solving all issues regarding how to structurally manufacture the tool.”

Tools range from a 1.8 tonne aluminium mould tool, 1.8 metres long and 800 mm wide, to those of just 50mm square. The average wax pattern tool is around 1.2 to 1.3 metres.

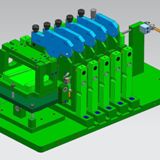

Their first 5-axis machining centre – a German Hedelius – joins eight 3-axis Taiwanese YCMs and Bridgeport in a recently extended 6,600 square foot factory at Plymouth. They are used to produce large wax pattern dies throughout the year, along with all the gating and auxiliary tooling.

The bulk of their contracts is for aluminium wax pattern tools, which are either hinged or a straight lift die, producing a wax pattern of the casting to go into the engine. “Using the investment casting process means we get perfect definition in the wax to turn it into the casting.”

“Because we’re in a niche market, we had to expand, both in terms of increasing the size of our factory and adopting 5-axis. Customers are demanding more and more work from us, and we need to respond quickly. The only way we could manufacture the tooling was to work extremely long hours.

“We’re saving so much time now with EDGECAM’s 5-axis toolpaths on the Hedelius.”

The customer model of the component that the tooling is required to make is loaded into their CAD system, and Mark Newcombe’s son, Andrew, designs the tooling around it. Once the design and assembly are approved, he imports parasolids into EDGECAM.

“We also make the jig plates for holding the components, so they’re imported too, then EDGECAM does the full programming for everything.”

Mark Newcombe explains that CAM engineer Lance Jobe generates the programs, along with tooling sheets and information for the shop floor. “Tooling is usually produced from aluminium, sometimes with brass slides. And a lot of fixtures are stainless steel. Due to EDGECAM being easy to use this does not cause any problems.

He says EDGECAM is a fully integral and invaluable aspect of their manufacturing process, and its 5-axis capability brings numerous additional benefits:

• Reduced cycle time by machining complex components in a single setup. In addition, dimensional accuracy can be significantly improved through the elimination of positioning errors between setups.

• Improved surface finish and extended tool life are achieved by orienting the tool to maintain optimum tool to-part contact at all times.

• Improved access to undercuts and deep pockets - through tilting the tool or component allows shorter series tooling to be employed, eliminating the

need for secondary setups.

• Reduced fixturing, as the cutter can be presented to the component at any

required angle.

“And it’s very easy to use. With the command prompts, the programs and machining sequences are so simple to generate.”

Because Andrew Newcombe has operated CNC machines he takes CAM requirements into consideration when designing the tools in CAD, and the only issue Tooltech had was trying to machine undercuts. “That’s why 5-axis is so important for us. It means we no longer have to turn the block for another set-up.

“Once Andrew completes the design on CAD we’re 100% confident that EDGECAM will produce it accurately, economically and fast. I promote our services to customers by showing them we have a 5-axis CAM system that can manufacture anything they ask us.”

Programs are created using a bespoke post processor which runs all their machines, including their latest 5-axis acquisition. “The advantages of running a bespoke post are huge, in terms of preventing errors. The one post is written for all our machines, so we have no variables.

“An EDGECAM engineer worked with Andrew and Lance, and we now have a post which provides code in exactly the format each machine needs it to be, whether it’s for the Hedelius, YCMs Bridgeport, or the graphite machine.”

And Tooltech’s 12 core processor gives even quicker CAM times. “We can move from EDGECAM to CAD, and the manufacturing programs continue to run in the background.”

About the Company

Name: Tooltech

Business: Wax injection and mould tool manufacturer

Benefits Achieved

- Reduced cycle time by machining complex components in a single setup. In addition, dimensional accuracy can be significantly improved through the elimination of positioning errors between setups.

- Improved surface finish and extended tool life are achieved by orienting the tool to maintain optimum tool to-part contact at all times.

- Improved access to undercuts and deep pockets - through tilting the tool or component allows shorter series tooling to be employed, eliminating the need for secondary setups.

Comments

“Also at that time, we produced a tool with ten set-ups on the block as it had some extremely complex features on it, and it took us three weeks to manufacture. A 5-axis machine, programmed with EDGECAM software’s 5-axis module would have completed it in a week, with only three setups”

Mark Newcombe, Tooltech Director