Turning Material Removal Rates Three Times Faster With EDGECAM Waveform

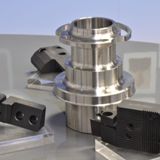

Figures show that EDGECAM’s new game-changing Waveform roughing strategy for turning, gives an overall Material Removal Rate that is three times faster than traditional machining when used in conjunction with Seco’s latest Duratomic® technology.

Following the success of the milling waveform technology EDGECAM’s latest release introduces a brand new turning cycle, Rough Waveform Turning. The toolpath maintains a constant cutting load, enabling significantly faster cutting data, and prolonging tool life. Similar to other turning commands, the cycle is sensitive to the stock condition, eliminating ‘fresh-air cuts.’

EDGECAM’s Strategic Partnership Manager, Wesley Tonks, says in trials conducted with Seco Tools combining EDGECAM Waveform with the next generation of Seco’s Duratomic® insert technology, the metal removal rate increased from 134.4 cm3 per minute to 448 cm3 per minute. “That’s over three times quicker. This is a significant improvement, as it enables machining facilities to remove material from the stock more efficiently for part completion.”

Duratomic technology increases a cutting tool’s toughness and abrasion resistance. Seco’s Sales and Marketing Manager Mike Fleming says, “although Duratomic® and Waveform can be completely standalone solutions, they complement each other perfectly, as the trials demonstrate.”

Cutting EN8 unalloyed medium carbon steel on a Mazak Integrex 200-lll machine tool with a 2 mm depth of cut, 0.8 mm/rev Stepover, and surface speed of 280 m/min, first using multi directional turning, and then with Waveform, the figures were:

Traditional:

Surface speed Vc (m/min): 280

DOC Ap (mm): 4

Feed Fn (mm/rev) 0.12

Material Removal Rate (cm3) 134.4.

Waveform:

Surface speed Vc (m/min): 280

DOC Ap (mm): 2

Feed Fn (mm/rev) 0.8

Material Removal Rate (cm3) 448.0.

Wesley Tonks says: “The Waveform roughing strategy is a high speed machining technique that maintains a constant tool cutting load by ensuring a consistent tool engagement into the material. The tool path moves in a smooth path to avoid sharp changes in direction, maintaining the machine tool’s velocity.

“As well as reducing cycle times and increasing the Material Removal Rate, Waveform also improves tool cutting life through less cutting force and better swarf management, lengthens machine maintenance cycles, keeps a constant chip load meaning there are no ‘spikes,’ and it cuts deeper, faster and smoother.”

The trial resulted in a 333 per cent material removal rate increase with 50 per cent less tooling, and an increase of 20 per cent in tool life.

Seco is partnering with EDGECAM at roadshows and events demonstrating how the combination of Waveform and Duratomic® deliver improved productivity, efficiency and reliability.The roadshows are on April 28, May 12, and May 19.

Registration is available at: http://www.secotools.com/en-GB/GB-United-Kingdom/Events/everywhere-you-turn/