Tombstone Module: One Of 50 EDGECAM Updates

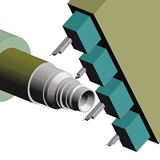

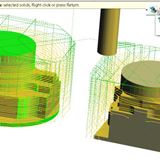

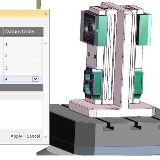

The new 2017 release of EDGECAM introduces a Tombstone module for assembling pre-existing parts on a defined mounting device.A simple dialog window enables users to add pre-machined part files, specifying the positions they are to be mounted on a tombstone or other multi-component work-holding device. Once they are assembled, EDGECAM automatically merges and rationalises all machining sequences by tool or index position and optimising the NC output into sub-routines.

EDGECAM Brand Manager John Buehler says: “This new feature offers huge time savings, as users no longer have to manually carry out the load, insert, merge and rationalize commands.”

There are just under 50 items of new and enhanced functionality in EDGECAM 2017 R1, covering turning, milling, wire EDM, machine configurations, and user experience.

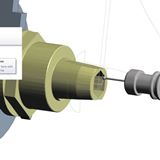

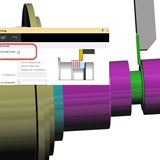

Amongst the updates, EDGECAM’s Code Wizard includes two highly significant enhancements in terms of machine tool configurations for lathes. When specifying Turret Type, the code wizard now supports Linear configuration. On this type of turret tools are mounted in a linear fashion, across either the X, Y or Z axis.

“This arrangement is largely used on Swiss-type machines, but in other normal configurations, too.”

Radially and axial mounted tools are also supported, in both single and multiple spindle environments.

Another new feature is a sliding spindle or material, providing support for machines where the tool is static but the material slides in and out of the chuck or collet. “Again, this is similar to Swiss-type machines,” says John Buehler.

Having supported probing on mills for many years, the latest release of EDGECAM introduces the same technology in the turning and mill-turn environment. Renishaw and m & h probing systems are supported, as well as a new Probe category in the Toolstore. Users can choose from a list of seven command cycles, all fully supported in the machine simulator.

Several background enhancements not only improve picking/highlighting when working with solid files, but show improvements in speed and part file manipulation. These enhancements come about through improvements to EDGECAM’s own internal engine, and by upgrading the OpenGL 3.3 technology.

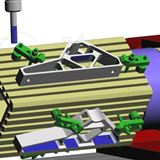

The Update Fixture command has been enhanced to include optimised Indexing moves. “Previously, users had to pick a safe Index position for the whole sequence. EDGECAM 2017 R1 removes this limitation, by automatically checking and correcting all Index Moves against stock and fixtures.”

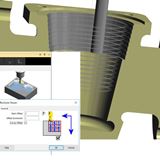

Additional updates have been made to the Rough Groove cycle…this time to include canned cycle support, through a Canned Cycle check-box. A further enhancement in the Turning environment sees most Turning Cam dialogs upgraded featuring pictures to define cycle functionality, which John Buehler says will be especially useful to new and infrequent users.

Users working with multiple components will gain significant benefits from two new features in the Insert Component command. “It’s now possible to insert separate machining sequences – whereas in the past all sequences had to be inserted, which, in certain set-ups, wasn’t necessary.” Also, CPL datum can now be selected from a simple drop-down menu.

The new release includes three specific enhancements for wire users – transformation, Fanuc technology, and Wireframe Feature Finder. The previous of EDGECAM introduced the Transform command, and this latest version evolves the Translate function within that, by adding two further significant time saving Transform commands: Rotate and Mirror, which also supports sub-routine output. And the new software also supports Fanuc a-C600Ia in the Technology tables.

The new Wireframe Feature finder command caters specifically for users working with 2D/3D wireframe CAD data. It removes the need to rely on Linked and Taper Profile commands, making it easier to work with intricate profile shapes.

The need to create stock to run the Machine Simulator has now been removed. A new command in the Preferences section now defaults EDGECAM to create stock automatically. When the system detects the absence of stock, it copies the component solid model, converting it to stock. “This offers significant time savings where the user simply wants to check a finishing cycle, or is working with Probing cycles.”

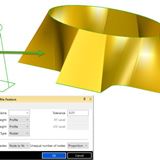

Three new pieces of functionality have been added to the Profiling cycle. Cut Increment Stand Off, under the Links tab, gives control of the cutter’s position during passes. The Helical function now has a Supress Helical Clean Up Pass Offset option in the Multiple Passes function determines the order of cuts. The Multiple Passes function now offers Cut By Offset, which allows the user to determine the manner in which the toolpath is distributed.

Numerous new features have been added to the Workflow and Planning Board automated machining commands, leading to toolpaths being generated faster. Strategies are now applied to both Main and Sub Spindles in the Turning environment, instead of only in Main, meaning the strategies now support the Spindle Set-Up command by transferring the workpiece from the Main to the Sub Spindle. And the introduction of Hole Finish Method in the Options dialog now allows Reaming to be specified as a method of finishing a hole feature by checking the hole’s finish attribute. A new Use Current Tool check-box in the Machine Feature option can force the strategy to use the current turning tool or milling cutter.

Session details have been added to Setup Browser and Rotational Handle on Dynamic CPL Marker within the Turning environment. John Buehler says these are ease of use enhancements. “Specifically with turning, users will notice that the CPL Marker looks simpler by just displaying the X and Z markers. The new marker can be used to dynamically rotate, pan and translate the component. The Set-Up window has been split into two distinct panels – Session, which displays environment and material information, and Set-Up dealing with datum and positioning. And when loading multiple parts the Set-Up window will individualise each solid model and automatically add a new CPL datum, meaning each model can be scrutinised individually, and datum altered.

There is no longer any need to program Rapid To Toolchange and Rapid To Home commands when working with turning and mill-turn machines, as this can now be set as the default.

And finally, a new option of Mating Location has been added when CPLs are created, signifying a machining sequence datum…along with Machine Location when inserting components. The main benefit of this is to filter out unnecessary CPL datum while using the Insert command, Index command or the new Tombstone function.